WhatsApp

WhatsApp

Nordplant™ solutions for aggregates crushing and screening are built using predesigned modules, which allow quick delivery and easy assembly to get your stationary plant up and running in the time you want. Whether you are building a complete, totally new plant or upgrading your existing plant, predesigned plants provide high efficiency and industrial performance for quick return on

WhatsApp

WhatsApp

IMPACT CRUSHING Impact crushers may be used as primary, secondary, or tertiary crushers. Despite having a somewhat higher operating cost than other crushers, they tend to produce a more uniform particle shape. Impact crushers usually will benefit the aggregate better than compression crushers, and they may generate more fines. Common types are

WhatsApp

WhatsApp

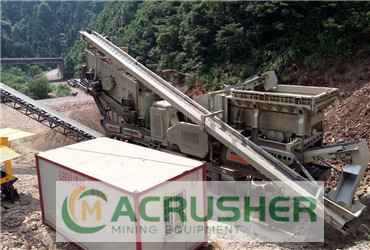

250TPH Tailing Construction Waste Crushing Plant. Material: Tailing Construction waste Capacity: 250TPH Application: Drymixed mortar, highquality aggregate and various kinds of building materials for sponge city construction Equipment: PEW Jaw Crusher, PFW Impact Crusher, HPT Multicylinder Hydraulic Cone Crusher, VSI5X Sand Making Machine, Vibrating Screen, Feeder, Iron Collector, Dust

WhatsApp

WhatsApp

Aggregate Impact Crushing Plant Cost. Impact crusher machine is used as the secondary crushing equipment in aggregate processing line. It will process the materials into smaller size. With 50260tph capacity, this aggregate impact crushing plant machine will meet different clients'' production needs. It is welcomed for the high quality and reasonable price cost. 50260tph Aggregate Impact

WhatsApp

WhatsApp

Cost Analysis for Crushing and Screening – Part II Development of a cost model for determination of the production cost for product fractions Johan Fägerlind Division of Production and Materials Engineering, Lund University 2015. I Preface This Master thesis was performed during the spring of 2015 at SRP AB in Svedala as the end of the candidates'' education in Master of Science in

WhatsApp

WhatsApp

how much is aggregate crushing plant cost; how much is aggregate crushing plant cost. Crusher . A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste .. Using this method also all Read More. Crusher . A crusher is a machine designed to reduce large rocks into smaller rocks

WhatsApp

WhatsApp

Environmental Impact Of Aggregate Crushing Plant . 202049aggregate crushing plant environmental negatives. Crushing Plant What Possible Impacts On Environment Zenith LT1620E mobile impact crushing plant This solution makes it possible to minimize all environmental impacts and the total production cost One of the biggest negative impacts of dust on the environment is the Free

WhatsApp

WhatsApp

In addition, the deep rotor vertical shaft impact crusher can be used for primary crushing,also can be used for secondary crushing. If equipped with the improved version of impact crusher that dedicated to return material crushing and shaping, the effect will be better and the cost of aggregate

WhatsApp

WhatsApp

In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher. When the processed material is easy to crush and not very abrasive, an impact crusher may be the best choice for primary crushing. One of the most important characteristics of

WhatsApp

WhatsApp

Cost of aggregate crushing plant,aggregate crusher cost centerless grinding machines overheats; jet jdc500 used for sale; for sale black and decker valve grinder td; Request Quotation. crusher run aggregate price. As a professional crushing and grinding equipments manufacturer, Next: studer grinding machine; Recent Updating. Request Quotation. Our crusher have very leading status in

WhatsApp

WhatsApp

Aggregate dry and wet impact value heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for.

WhatsApp

WhatsApp

SmartPlant ™ aggregate plants are made of SmartStations that can be mixed and matched to meet your needs for maximum productivity and performance. Intelligence builtin SmartPlants utilize ''s stateoftheart RD and technological innovations to provide new ways to

WhatsApp

WhatsApp

aggregate crusher plant cost in pakistan heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

WhatsApp

WhatsApp

QUALITY, RELIABLE AGGREGATE PROCESSING an emphasis on custom solutions, Aggretek is a company dedicated to the aggregate processing industry. With our extensive experience over the years in stationary and mobile processing systems, we give the consumer and dealer the highest quality of equipment and operational support available in the market today.

WhatsApp

WhatsApp

Crushing Plant for sale rental | Rock Dirt. Search from 1000''s of listings for new used Crushing Plants for sale or rental updated daily from 100''s of dealers private sellers.

WhatsApp

WhatsApp

costs of 50 tph aggregate crushing plant FULL LINE Mine Equipment Design roller bearing cone crushers, jaw and impact crushers, horizontal and incline screens through material low operating costs and the highest resale value at tradein time.

WhatsApp

WhatsApp

China Artificial Aggregate Plant and Cost for Aggregate Crushing Plant/Crushing Plant, Find details about China Crushing Plant, Artificial Aggregate Plant from Artificial Aggregate Plant and Cost for Aggregate Crushing Plant/Crushing Plant Shibang Industry Technology Group Co., Ltd.

WhatsApp

WhatsApp

Impact Crusher. Impact crushers produce more consistent and predictable aggregate with a firmer particle size distribution, higher output, and cheaper startup cost than jaw crushers. From: Waste and Supplementary Cementitious Materials in Concrete, 2018. Related terms: Ball Mills; Crushers; Silos (Agricultural) Kilns; Cement Plant; Jaw Crusher

WhatsApp

WhatsApp

How to reduce impact crusher wear parts cost in aggregate crushing plant? Source: Author:Great Wall Posted: Views: Impact crusher best technical characteristic is able to produce high quality stone granule shape, impact crusher has the crushing and reformation performance.

WhatsApp

WhatsApp

The largest primary gyratory crushers cost US 2 million or more, while overall crushing plant costs can be as high as 18 million. It''s necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects:

WhatsApp

WhatsApp

Crusher plant, which is also called crushing and screening machine, is a set of equipments which could crush large block material by multistage crushing and screening on the basis of specific discharge specifications. And users can adopt different disposition form according to the variety and size of raw material and the requirement of finished material. Crushing plants are mainly applied to

WhatsApp

WhatsApp

Sepro Aggregate Systems designs and fabricates portable crushing plants that utilize Sepro equipment, other OEM equipment, or customer supplied crushing and screening equipment. Plant design revolves around creating plants that are safe, easy to maintain and easy to configure for over the road towing with a minimum of disassembly required. Sepro has a team of expert engineers to build

WhatsApp

WhatsApp

Impact crusher is rarely in the aggregate processing plant alone, only when combining with the vertical gyratory crusher. The vibrating screen divides into the sideling type and flat type, sideling type more power saving than the flat vibrating screen. Generally, the fine particle screens are a single layer or double layer, but the finished product screen is multiple layers for the most part

WhatsApp

WhatsApp

China Artificial Aggregate Plant and Cost for Aggregate Crushing Plant/Crushing Plant, Find details about China Crushing Plant, Artificial Aggregate Plant from Artificial Aggregate Plant and Cost for Aggregate Crushing Plant/Crushing Plant Shibang Industry Technology Group Co., Ltd.

WhatsApp

WhatsApp