WhatsApp

WhatsApp

The smelting of aluminum begins with the extraction of bauxite ore by a form of open cast mining. The bauxite is washed and screened before being converted to alumina, a white powdery element from which the aluminum is produced. Aluminum smelting is carried out in a Hall Heroult reduction cell, which is lined with carbon. A mix of alumina and cryolite is fed into the cell and carbon blocks ...

WhatsApp

WhatsApp

The concentration of Ore can define as the chemical process of eliminating impurities like sand, rocks, silt, grit etc. from the ore for the extraction of metal. In this content definition and methods for the concentration of ore are explained along with the definition of ore and its types.

WhatsApp

WhatsApp

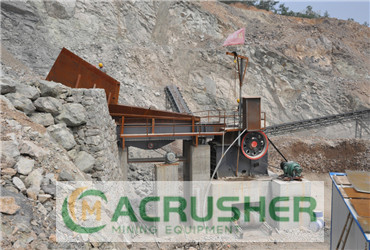

download modular simulator for ore dressing plants slag Plant process crusher mining equipment coppergold processing equipment,..slag crusher underwater. Inquire Now; iron ore mining companies in kenya Mining in Kenya. Mining in Kenya yields highgrade quantities of gold copper ilmenite and tantalum. Kenya is also an important source of nonmetallic minerals including soda ash ...

WhatsApp

WhatsApp

The Process: Bauxite to Alumina to Aluminum. Aluminum is hidden in an ore called Bauxite. It''s a red dirt and clay mixture commonly found in Australia, Brazil, and India. If you''re looking for shining bits of silver in the ground, though, you won''t find it. Aluminum as we know it has gone through a lot to get to our supermarket shelves (among other amazing uses). Bauxite is collected ...

WhatsApp

WhatsApp

JinPeng Mining has very strict production management and advanced production technology, and has achieved ISO 9001: 2008. We own various kinds of devices such as: CNC automatic cutting machine, CNC automatic welding machine, 5 meters vertical CNC lathe, CNC lathe, CNC boring machine, and the largest lathe in Shandong provence with 15m length, all those support Jinpeng Mining guarantees the ...

WhatsApp

WhatsApp

Bauxite ore is the most common raw material used for producing alumina, which is the feedstock for aluminium smelting. Bauxite is a group of aluminium oxides. Bauxite is a group of aluminium oxides. Bauxite is named after the town of Les BauxenProvence in France, which is where the geologist Pierre Berthier first identified the mineral in 1821.

WhatsApp

WhatsApp

Aluminium Industry is the second most important metallurgical industry in India. Aluminium has gained popularity as a substitute of steel, copper, zinc and leads in a number of industries because ...

WhatsApp

WhatsApp

In honor of Throwback Tuesday, we are revisiting MetalMiner''s Top 50 posts with an eye toward illuminating what''s happening in metals today. #TBT This post, originally published Feb. 26, 2009 ...

WhatsApp

WhatsApp

Introduction of Xinhai Leadzinc Ore Dressing Process 14:35:19 XinHai Views (3165) Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here, and contact us online.

WhatsApp

WhatsApp

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

WhatsApp

WhatsApp

Production. In nature, aluminum does not exist in a pure state. The production of primary aluminum metal begins with bauxite ore, which is composed of hydrated aluminum oxide (40% to 60%) mixed with silica and iron oxide. It takes approximately 4 to 5 tonnes of bauxite ore to produce 2 tonnes of alumina. In turn, it takes approximately 2 tonnes ...

WhatsApp

WhatsApp

Aluminium is the most abundant metal in the Earth''s crust, occurring as bauxite which contains aluminium oxide. The first step in producing aluminium is mining this ore. Bauxite occurs mainly in tropical and subtropical areas, like Africa, the Caribbean, South America and Australia. Australia is the largest producer of bauxite, with five large mines supplying around 30 per cent of global ...

WhatsApp

WhatsApp

The first was the invention of a new process for obtaining aluminum from aluminum oxide. Charles Martin Hall, an American chemist, and Paul L. T. Héroult, a French chemist, each invented this process independently in 1886. The second was the invention of a new process that could cheaply obtain aluminum oxide from bauxite. Bauxite is an ore that contains a large amount of aluminum hydroxide (Al

WhatsApp

WhatsApp

Aluminum decreased USD/Tonne or % since the beginning of 2020, according to trading on a contract for difference (CFD) that tracks the benchmark market for this commodity. Historically, Aluminum reached an all time high of in July of 2008.

WhatsApp

WhatsApp

Production costs for smelters are highly dependent on the global economic environment, which affects oil prices, and the prices of other commodities, including those that create smelters'' input costs. For instance, during the global economic crisis in 2009, production costs for aluminium smelters decreased between 30 and 40% compared to the record high costs in [.]

WhatsApp

WhatsApp

advantage of service Confidence comes from strength. We only focus on the mill in nearly 40 years, from the initial technology introduced to the success of a large number of independent research and development of patent technology is applied to the practical production operation, dare to innovation, the pursuit of quality, beginning the end adhere to high quality products, professional ...

WhatsApp

WhatsApp

Using automated ore processing machines increases the ratio of Ore to Ingot and/ or speed up the process. Whatever the Mod a Player chooses to use to build his Facility, the first step is to set up a diversion for unwanted items such as Dirt and Cobblestone using chests or other storage with an overflow to a Void Transport Pipe or Trash Can .

WhatsApp

WhatsApp

By processing the aluminum ore, the refined alumina can be used in many industries, such as electrolytic aluminum, ceramics, medicine, electronics, machinery and other industries. With the development of these industries, the requirement of alumina is becoming larger and larger. As we all know, aluminum ore must be crushed before refining. recommends a production line for .

WhatsApp

WhatsApp

Demand for aluminium is growing worldwide Global primary aluminium production increased by percent in 2017. Continuing strong demand is also being reflected in price trends and has had an enormous impact on the level of international aluminium stocks. Aluminium will continue to benefit from the trend towards lightweight construction in coming years. Global primary aluminium production ...

WhatsApp

WhatsApp

The Bayer process for refining aluminum ore, developed in 1888 by an Austrian chemist, also contributed significantly to the economical mass production of aluminum. In 1884, 125 lb (60 kg) of aluminum was produced in the United States, and it sold for about the same unit price as silver. In 1995, plants produced billion lb ( million metric tons) of aluminum, and the price of silver ...

WhatsApp

WhatsApp

American Chemical Society: Chemistry for Life. ... In 1886 Charles Martin Hall invented an economical electrochemical process to release aluminum from its ore. Until then, this light, lustrous and nonrusting metal was rare and costly. A group of Pittsburgh investors, headed by metallurgist Alfred E. Hunt, agreed to support the commercialization of Hall''s process and founded the Pittsburgh ...

WhatsApp

WhatsApp

PbZn ore divides into sulfide PbZn ore and oxide PbZn ore . Flotation is the most widely used in separating sulfide PbZn ore, to separate zinc and plumbum, sometimes for separating sulfide iron and other minerals . Sulfide PbZn ore process divides into priority flotation process, mixseparating flotation, asynchronous flotation,and so on .,It is a high technological enterprise that ...

WhatsApp

WhatsApp

Ore dressing Bayer process is a typical chemical metallurgical process for producing alumina. It involves manifold of danger and harmful factors. The paper analysis and points out danger and harmful factors will appear during production after it''s investigation and studying on the existing domestic production equipment, also combines with instance of other alumina refineries.

WhatsApp

WhatsApp

Production planner Enter the number you wish to produce per minute, the calculator will try to find a possible solution to provide a valid production chain. You can drag the network graph with the mouse, zoom in/out with the mouse wheel.

WhatsApp

WhatsApp