WhatsApp

WhatsApp

Solid rock is estimated at to 3tons per cubic meter. If rock is crushed into uniform sizes, the presence of open space between the particles causes the load to be lighter approximately tons per cubic meter. Mixed sizes of crushed rock can range from to tons per cubic meter.

WhatsApp

WhatsApp

Density Values of Different Construction Materials. If two different materials are same in weight, but their density of both may be different. Lower dense material occupies more volume than higher dense material. Density also decides the sinking property of material. It is decided by knowing the density of liquid. If the material has lower

WhatsApp

WhatsApp

· Nuclear density determination on gravel with no fines is not particularly accurate whether you use backscatter or direct transmission. For determination of inplace density, use a direct volume replacement method such as the rubber ballon method (hard to find these days. You can also use the sandcone method, but you''ll have to isolate the voids in the gravel by using Saran wrap to line the

WhatsApp

WhatsApp

Rock Density and Hardness Some displacement is required to prepare a muckpile for efficient excavation. The density of the rock is a major factor in determining how much explosive is needed to displace a given volume of rock (powder factor). The burdentocharge diameter ratio varies with rock density, changing the powder factor. The average burdentocharge diameter ratio of 25 to 30 is for

WhatsApp

WhatsApp

Aggregate crushing value test on coarse aggregates gives a relative measure of the resistance of an aggregate crushing under gradually applied compressive load. Coarse aggregate crushing value is the percentage by weight of the crushed material obtained when test aggregates are subjected to a specified load under standardized conditions.

WhatsApp

WhatsApp

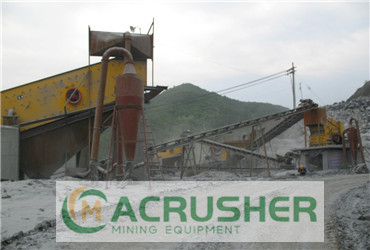

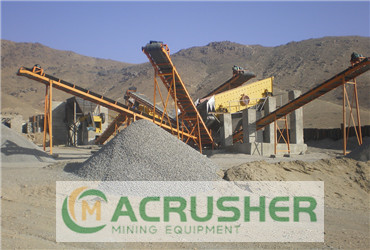

of bulk density of material after crushing heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

WhatsApp

WhatsApp

Soil or rock from the borrow expands when dropped on the lorry or the landfill or stockpiled. One cubic from the borrow does not translate to one cubic dump. Bulking or swell factors for some materials: Material Density at the Borrow 10 3 (kg/m 3) Bulking (Swell) Factor (%) Basalt: : 75 80: Clay: : 20 40: Dolomite: : 50 60: Earth: 20 30: Gneiss: : 75 80

WhatsApp

WhatsApp

Bulk Density Determination After Crushing. Bulk density of iron ore in india. This includes the determination of the specific gravity machines used to mine ironore module and tracked crushing plants iron. Send Message Get a Quote. Relate Product. Ceramsite Production Line; Basalt/Diabase Stone Crusher; Wollastonite Grinding Mill; Lithium Ore Processing Equipment; Density Of 19Mm Crushed

WhatsApp

WhatsApp

of bulk density of material after crushing heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

WhatsApp

WhatsApp

What is the Density of crushed stone The QA wiki. /m3 (+/ 10%). The above answer is for solid rock, generally not crushed stone. Crushed stone of uniform size has a nominal density

WhatsApp

WhatsApp

Rock fragments produced by the crushing and screening of basic igneous source rock which conforms to the requirements of Section 801 (Source Rock for the Production of Crushed Rock and Aggregates) of the VicRoads Standard Specifications for Roadworks and Bridgeworks. Produced in a controlled manner to close tolerances for grading and plasticity. Technical Information Sheet CLASS 2 3 CRUSHED

WhatsApp

WhatsApp

As specific gravity is just a comparison, it can be applied across any units. The density of pure water is also lbs/ (pounds per cubic foot) and if we know that ammonium nitrate has a sg of then we can calculate that its density is x = lbs/ Note, kg/ divided by = lbs/ [back to conversion home page ] [ density of liquids] [ density of water

WhatsApp

WhatsApp

Rather depends on what the parent rock is. Some rock is more dense than others. Supposing it is granite, the density of the rock before quarrying is about to /m3. Crushed material typically is around /m3 for concrete aggregate size

WhatsApp

WhatsApp

® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations on secondary, tertiary or quaternary crushing stage. It is designed for high productivity, low operating and wear costs, long service life and high efficiency, providing high quality product. Benefits. Optimized performance. Revolutionary

WhatsApp

WhatsApp

Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery. Some crushers are mobile and can crush rocks as large as meter (60 inches). Primarily used inpit at the mine face these units are able to move with the large infeed machines (mainly shovels) to increase the tonnage produced.

WhatsApp

WhatsApp

How to EASILY Identify Rocks and Minerals: Have you ever found a rock and wondered what it was? Or maybe you have an old collection but can''t remember what hidden treasures you actually have? Well, you''re in luck. By doing a few simple tests you can discover how valuable those useless chu

WhatsApp

WhatsApp

density after crushing rock; density crushed gravel, crushed stone bot aggregates limited crushed stone bot aggregates limited crushed aggregate 19mm crusher run liCGMne 19mm crusher run liCGMne can be considered the equivalent to granular a opss from density of 19 crushed stone. Oline Chat . Density of crushung rock associazionegeit. density after crushing rock saluteindia in density after

WhatsApp

WhatsApp

· right so you get a range from 104 131 pcf depending on just the SG. Also, the void ratio varies depending on the type of rock and procedures used to mine and crush it. So like I said, with all the variables, if you want the correct weight you need to ask the supplier. If you want a ball park plus or minus 10 or 15% than just use 120.

WhatsApp

WhatsApp

The extraction of hard rock that is turned into various crushed stone grades is a great economic indicator. Crushed stone is and will continue to be a very integral part of things we build. If you are working on a construction project and need help deciding what crushed stone grade you need, or need crushed stone in bulk for delivery, contact Braen Stone for more information. By Dirk Braen

WhatsApp

WhatsApp

In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface. Less abrasive and softer rocks or stones

WhatsApp

WhatsApp

density of 19 crushed stone Crushing Equipment. Bulk density. Mix design and how the crushed stone is sorted after crushing. Determination of the apparent density of.

WhatsApp

WhatsApp

® HP300™ cone crusher is a versatile rock crushing machine frequently utilized as a secondary, tertiary, or quaternary crusher in aggregates production or in mining operations. It is part of the world''s most popular cone crusher series, and designed for high productivity, with low operating and wear costs. Benefits. Optimized performance. Revolutionary combination of crusher speed

WhatsApp

WhatsApp

Density of Some Common Building Materials: These values for density of some common building materials were collected from sites across the Internet and are generally in agreement with multiple sites. Most are from BOCA or ASAE tables. However, if you have values that you believe are more accurate, use them for your calculations, and please send me an email to let me know what your values are

WhatsApp

WhatsApp

Slurry Densities Calculate density of a slurry; Soil and Rock Bulk Factors Soil and rock expansion or swell after mining; Water Density, Specific Weight and Thermal Expansion Coefficient Definitions, online calculator, figures and tables giving Density, Specific Weight and Thermal Expansion Coefficient of liquid water at temperatures ranging from 0 to 360 °C and 32 to 680°F

WhatsApp

WhatsApp