WhatsApp

WhatsApp

Hosokawa Micron are able to supply powder processing equipment for a wide range of fine grinding and classification applications that deliver consistent, one pass particle size reduction in the range 15 – 35µ or even finer.

WhatsApp

WhatsApp

Fine powder is produced by an integrated production system from raw material treatment to finished products by fully utilizing the latest cuttingedge production equipment and our unique highlevel machining technology. Under the consolidated manufacturing management, raw materials are pulverized to micron levels of 1 to 100 by ultrafine

WhatsApp

WhatsApp

The ultra fine grinding mill equipment prepared by Clirik is a deepprocessing grinding mill equipment that assists in grinding fine powder. The fineness of the powder made by ultra fine grinding mill can be adjusted between mesh. Grinding Mill Equipment for Bauxite Grinding

WhatsApp

WhatsApp

Powder Coating Powder Screening Screening of powders, new and reclaimed, will insure uniform particle size distribution, separate out contaminants, and allow the system operator to fine tune the application equipment without puffing or surging for maximum transfer efficiency and finish quality.

WhatsApp

WhatsApp

Our base of knowledge, expertise and experience in the material handling of granular and powder products in food processing has been significantly increased beyond pneumatic conveying. We can now provide new or refurbished food processing plants, with purposebuilt components optimised for granules, powders and extruded piece handling.

WhatsApp

WhatsApp

Continuous processing equipment, from single units to complete systems. Flash dryer; Subscribe to receive occasional newsletters on our powder process technologies and entry vouchers for trade fairs. Service Hotline. Available 24/7. Call +31 314 373372 or 505 (after office hours).

WhatsApp

WhatsApp

Quadro''s reduction equipment is ideal for multiple applications with our dry wet milling, sieving, deagglomeration, and reclaim capabilities. Industry Applications for Powder Milling and Bulk Powder Processing

WhatsApp

WhatsApp

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products. Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is around a d50 of 80 microns.

WhatsApp

WhatsApp

Smart solutions for safe, hygienic processing . Microbiological safety must be ensured at every stage of the milk powder process. Our portfolio of separators and ceramic microfiltration systems physically remove heatresistant bacteria and spores from milk and whey, with minimal impact on taste, nutritional content, or other final product properties.

WhatsApp

WhatsApp

Wide range of powder processing machinery Hosokawa Micron''s wide range of powder processing machinery comprises innovativelydesigned and expertlyengineered mixing, drying, agglomeration, milling and containment technologies, as well as ancillary equipment, assembly, commissioning, onsite training and process optimisation.

WhatsApp

WhatsApp

of PTFE Fine Powder Processing 1Rheology, the science of flowing materials and deformation. It was established because the linear elasticity theory with Hook''s law and hydrodynamics with Newton''s law of friction were not sufficient to describe the deformation behaviour of certain substances.

WhatsApp

WhatsApp

Our six Littleford reactors allow DTI to process a wide variety of chemistries with unmatched processing flexibility. We are capable of stripping off water and/or solvents during the viscous dough phase and take products from a slurry to a fine powder with less risk and time than other drying technologies.

WhatsApp

WhatsApp

Manufacturer of Air Classifier Mills Powder Processing Solutions. CMS has delivered innovative solutions, milling technologies, and mill systems to diversified industries globally for nearly 30 years. And we''re just getting started. About Us Our Systems

WhatsApp

WhatsApp

Powder ProcessSolutions is a leading provider of dry ingredient processing solutions, products and services for the food, dairy, nutrition, pharmaceutical and chemical industries. Our products like the BFM fitting and MAGNATTACK™ magnetic separators are designed to help improve the safety and efficiency of

WhatsApp

WhatsApp

Spiroflow is a global leader in the field of powder handling and dry solids processing and an emerging leader in control systems integration. Throughout our 45year history, our design engineers and process automation team have provided customers with the safest, most efficient, innovative and most reliable process solutions available.

WhatsApp

WhatsApp

Grind Equipment, Chemical Machinery, Micronizer manufacturer / supplier in China, offering High Quality Fine Powder Impact Pin Crusher Mill, Guar Gum Bean Micron Powder Grinding Mill Machine, Stainless Steel Cabinet Automatic Vacuum Mixer for Investment Powder and so on.

WhatsApp

WhatsApp

For coarse or fine particle size reduction, Bepex has the industrial process equipment solution to meet your needs. Bepex can provide a single technology for onestep particle size reduction, or incorporate those technologies into a complete size reduction system to solve your industrial process application.

WhatsApp

WhatsApp

Fine powders, granules as well as (coated) pellets can be processed simultaneously. Depending on the material, the shear rate can be varied. DosiBox® proper consists of a transparent PE container in a sanitary quality to food processing requirements, with an integrated dosing screw. The container sits in a sturdy, fourlegged supporting

WhatsApp

WhatsApp

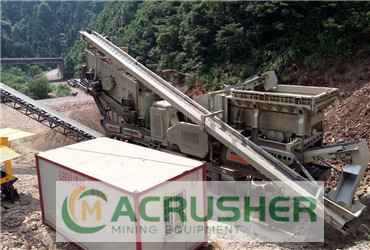

ia jaw crusher processing dry powder mortar. Main Specifications of Mobile Jaw Crushing Plant Special Dry Powder Mortar Plant QH40 Series Dry Powder Mortar Plant Field processing convenient form small turning radius The configuration of related equipment should be based on the user''s requirements It can crush crush and fine ore The jaw mobile crusher can remove the circular vibrating

WhatsApp

WhatsApp

Stone powder grinding mill is the key equipment used in stone production line It includes the dry and wet grinding line with ball mill vertical roller mill and so on crusher equipment and grinding mills for Gabbro Crushing Processing production line Granite ore crushing processing equipment for sale Leptite Processing Plantfor Sale . Get Price

WhatsApp

WhatsApp

Fluid Energy provides exceptional toll powder processing services. Our powder grinding plant has been in the powder processing business for more than 20 years; we have the equipment and the experience required to expertly process a wide variety of materials for an assortment of industries.

WhatsApp

WhatsApp

Powder processing operations can generate vast quantities of electrostatic charge via the movement of powder. The standard method of charging on powder processing operations is due to triboelectrification, which is basically the contact and separation of the powder with processing equipment, the powder itself, or other factors that can cause charging, like surface contaminants.

WhatsApp

WhatsApp

The fine powder will be brought to the classifier, and then, the qualified fine powder will flow out the mill and be collected by dust collector, other coarse powder will be brought down to the millstone by the blade of classifier and be ground again. The circulation like this is the overall process of grinding. Application Range

WhatsApp

WhatsApp

Coffee grinding is a crucial step in coffee processing and, when done properly, can dramatically improve coffee extraction and aroma retention, thereby optimizing the brewed coffee quality. As the leading grinding equipment manufacturer, we have led the industry in research and development of

WhatsApp

WhatsApp