WhatsApp

WhatsApp

Jaw Crusher Spare Parts and Wear Parts Jaw Plate for Stone Crushing and Screening Short Description: JAW CRUSHER SPARE PARTS is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heattreatment process.

WhatsApp

WhatsApp

China Mining Cruher High Manganese Steel Crusher Spare Parts Fix Jaw Plate for Jaw Crusher, Find details about China Jaw Plate, Fixed Jaw Plate from Mining Cruher High Manganese Steel Crusher Spare Parts Fix Jaw Plate for Jaw Crusher Zhejiang Wujing Machine Manufacture Co., Ltd.

WhatsApp

WhatsApp

casting steel jaw crusher jaw crusher machine. casting jaw crusher, hsm stone crusher machine casting steel jaw crushers. 1 set (min. order) gongyi city hua sheng ming heavy industry machinery factory. 2016 High Strength Casting Steel Stone chongqing mixing plant crusher highquarry crusher,high manganese steel casting jaw plate reserved parts of rock crushing machine, jaw crusher

WhatsApp

WhatsApp

Jaw crusher for sale, manganese steel jaw crusher Alibaba . Jaw crusher for sale, manganese steel jaw crusher,US 5,000 30,000 / Unit, New, Jaw Crusher, dolomite from Zhengzhou Toper Industrial Equipment Co

WhatsApp

WhatsApp

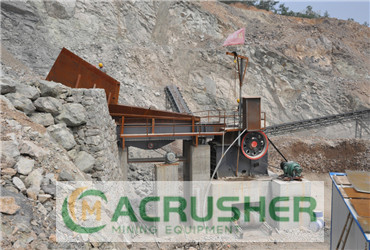

Crushing is one of the preliminary stages in mineral processing from the ore. The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel

WhatsApp

WhatsApp

MEKA Jaw Crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness and lowcost operation The optimalangle toggle plate generates extra crushing force and at the same time provides security for the drive system. Reversible high manganese cast steel jaw plates. Different

WhatsApp

WhatsApp

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure ).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure (a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

WhatsApp

WhatsApp

Aug 18, 2020· 2013 QJ341 Jaw Crusher. This machine has a massive jaw opening 47"x29". Maximum Feed Size is 25"6'' Single Toggle C12 Jaw Crusher. Engine is a Acert, 355hp.

WhatsApp

WhatsApp

Steel plate jaw crusher for crushing sto. Stone Crushing Machine Steel plate jaw crusher for crushing sto We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs.

WhatsApp

WhatsApp

China Jaw Crusher Part Swing / Fixed and Movable Jaw Plate Tooth, Find details about China Jaw Plate, Swing Jaw Plate from Jaw Crusher Part Swing / Fixed and Movable Jaw Plate Tooth Zhejiang Wujing Machine Manufacture Co., Ltd.

WhatsApp

WhatsApp

Jul 28, 2020· For the largesized jaw crusher, the large rocks and stones make the jaw plate wear seriously. Therefore, the high manganese steel can be used as the material of the jaw plate. Due to the jaw plate is usually formed into a vertically symmetrical shape, it can be inverted to use secondly. How to protect your jaw crusher parts Efficiency Improvement:

WhatsApp

WhatsApp

The jaw crusher spare parts mainly include the fixed jaw plate and the movable jaw plate. ''s jaw crusher plates are made of super high manganese steel, therefore they have a service life 50~ longer than those made of traditional high manganese steel.

WhatsApp

WhatsApp

PE Jaw crusher Crusher machine China Jaw crusher, 202062 " jaw assembly adopts high quality casting steel, heavy eccentric shaft adopts forging steel processing, the machine with transcendental stability. 2. Comparing with the same size jaw crusher, we adopt more durable eccentric shaft bearing, so the bearing capacity is big. 3.

WhatsApp

WhatsApp

Fixed and movable jaw plates are the two main components. A motordriven eccentric shaft through suitable hardware makes the movable jaw plate travel in a regulated track and hit the materials in the crushing chamber comprising a fixedjaw plate to assert compression force for crushing. Coal Hammer Crusher. A coal hammer crusher is

WhatsApp

WhatsApp

Steel plate jaw crusher for crushing sto. Jaw Crusher High Standard Cruhser Manufacturer And . The crushing method of the jaw crusher is a curved extrusion type The operation principle mainly simulates the two movements of the animal During operation he motor drives the belt and the pulley which can be move up and down through the eccentric shaft It has the highmanganese steel plate and

WhatsApp

WhatsApp

This crusher is the finest of our lines of jaw crushers which we offer. Others include: Superior, Type "B" Blake, FineReduction and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. LOWER JAW CRUSHING COSTS As you compare this jaw crusher feature for feature with other makes

WhatsApp

WhatsApp

ASJE jaw crusher has the characteristics of high capacity, jaw plate wear resistance, high degree of humanized operation, good stability, simple structure and appearance which is the suitable choice for crushing processing with compressive strength less than 300 mpa.

WhatsApp

WhatsApp

Steel Plate For Crushing Black Stone Jaw Crusher Crusher West Java. Stone Crusher is the widely used as primary crusher machine for crushing process. Stone crusher is needed to crush the large stone into small particles in order to make stone aggregate or stone powder.

WhatsApp

WhatsApp

stone crushing jaws plates one of the most popular stone crushing machines in the world, jaw crusher is crusher, jaw breaker, stone jaw crusher, plates,with strong and. crushing bits used in crushers crusherasia. china ce approved favorable price mobile rock crusher the movable jaw and movable jaw plate will ce certificate mini rock crusher for stone and ore crushing.

WhatsApp

WhatsApp

In some designs, the toggle plate consists of two steel plates joined together by socalled "SHEAR BOLTS" bolts. These are bolts of known shear strength. If the crusher can not break things into the crushing chamber accidentally, when the jaw is not easy to break objects, these bolts will be cut.

WhatsApp

WhatsApp

As the genuine OEM parts supplier for all kinds of crusher jaw plates, JYS Casting stock and supply the entire range of products to suit the entire jaw crusher range across all jaw crushing Casting offer all jaw plate profiles, from the supertooth jaws profile for recycling and quarrying applications through to the multitooth jaws for tarmac and sticky types of aggregates.

WhatsApp

WhatsApp

Crushing Cavity Working Part. It mainly is consisted of fixed jaw plate, movable jaw plate, side liners, guard board and etc., and it is the working parts for breaking materials; 4. Safety Device. It consists of bracket, bracket base, spring, spring rod and etc., and it is the parts that play a security role during crusher works in an abnormal

WhatsApp

WhatsApp

Throughput is 8 tons/hr at a discharge of <3/4″. Perfect for crunching granite, quartz, pavers, tile, concrete, or other slab materials. All MBMM crushers feature oversize spherical roller bearings, cast manganese steel jaw plates, and come with a one year warranty. Turnkey solutions are available, inquire for additional details..

WhatsApp

WhatsApp

The LJ3055 jaw crushing plant is the newest jaw crusher in the Lippmann product line. Featuring an opposing wedge design, it is perfectly suited for any size job. The chassis has been created to accept any application you requirehopper removable system, extended discharge conveyor to feed a secondary or screen plant, diesel or electric

WhatsApp

WhatsApp